When Warren Buffett stated, “Price is what you pay, value is what you get,” he could have been speaking directly to today’s engineering and procurement experts tasked with selecting critical electromechanical components for industrial, energy storage and e-mobility applications. Their challenge is to decide based on cost, quality, service life and sustainability, all at the same time.

Without doubt, ESG requirements have tightened, and global warming is advancing faster than we previously imagined. However, cost pressure, customer expectations, competition, and a host of macroeconomic challenges are also intensifying, making it harder to secure long-term success. So how do you decide?

Clearly, for the transition to a climate-neutral economy to occur, clean technology needs to have a lower total cost of ownership (TCO) to stand a chance of being adopted over traditional components. Battery and solar technology are a case in point where dwindling prices allow business decisions that are fully aligned with environmental targets.

Total cost of ownership in electrical component selection

In industrial automation and electrification, total cost of ownership has become an essential metric because it calculates not only the purchase price but all costs until the end of an electrical component’s lifetime. This includes operating costs, set-up and ongoing maintenance costs, service-life before replacement and more.

This more holistic approach transforms component selection from a narrow financial calculation into a strategic decision. Indeed, according to research from Deloitte, procurement leaders named “addressing total lifecycle/ownership costs” to be among their top five strategies to deliver value to their respective enterprises. At the same time, procurement departments are often stretched thin: Calculating each single cost component in a TCO analysis may be unrealistic and overdone.

The hidden cost of energy losses

Inefficiencies in electromechanical components are a challenge in energy, e-mobility and industrial systems. Seemingly modest components controlling the power flow, such as contactors, can have very different effects on operational costs. Schaltbau and Eddicy customers and their (end) customers buy, store and/or sell energy via their applications – be it electric vehicles, charging stations, energy storage solutions or test benches – obviously, they don’t want to lose it.

How can a contactor contribute to energy efficiency? Resistance is the parameter where energy loss within the contactor can occur and which can be affected. To do this, contactors need to optimize their coil consumption and to keep their contact resistance as low as possible. Schaltbau’s Eddicy contactors provide best-in-class efficiency because of their massive AgSno2 contact tips (versus pure copper or thin-film plated contact tips) and electronic control for the optimal power consumption both at pull in and holding. As a result, contact warming is two- to three times lower than comparison competitors.

Less energy loss in the coil circuit and at the contact tips translates into reduced (energy) costs, better ranges and optimized thermal management/cooling for e-vehicles and e-charging, and lower total operational costs for energy storage systems. While some applications may only need two contactors, most charging stations require at least a half dozen. And energy storage systems easily contain dozens or hundreds of contactors which are in operation 24/7. Even small differences in energy efficiency can add up quickly.

TCO calculator: Show don’t tell

Eddicy’s direct current (DC) contactors have a unique selling point: As their coil consumption and power losses are much lower compared to competition, the (end) customer will save energy and costs in their system over the full product lifecycle. This benefit is not just a promise, but a proven result.

Schaltbau’s TCO calculator compares the total cost of contactor power loss for your entire application using Schaltbau contactors vs. competitor products. The calculation inputs the respective contactors’ voltages (V), thermal current (A), contact resistance (mΩ) and coil power loss (W). It then calculates the power loss per pole, namely, the energy loss via contact resistance and coil consumption, the total energy loss (kWh/year) as well as the total cost of contactor power loss for the entire system. The calculation can be adjusted to the respective energy price a customer pays, the number of contactors to be installed in their systems, the number of hours per day the system is running and the expected contactor lifetime before replacement.

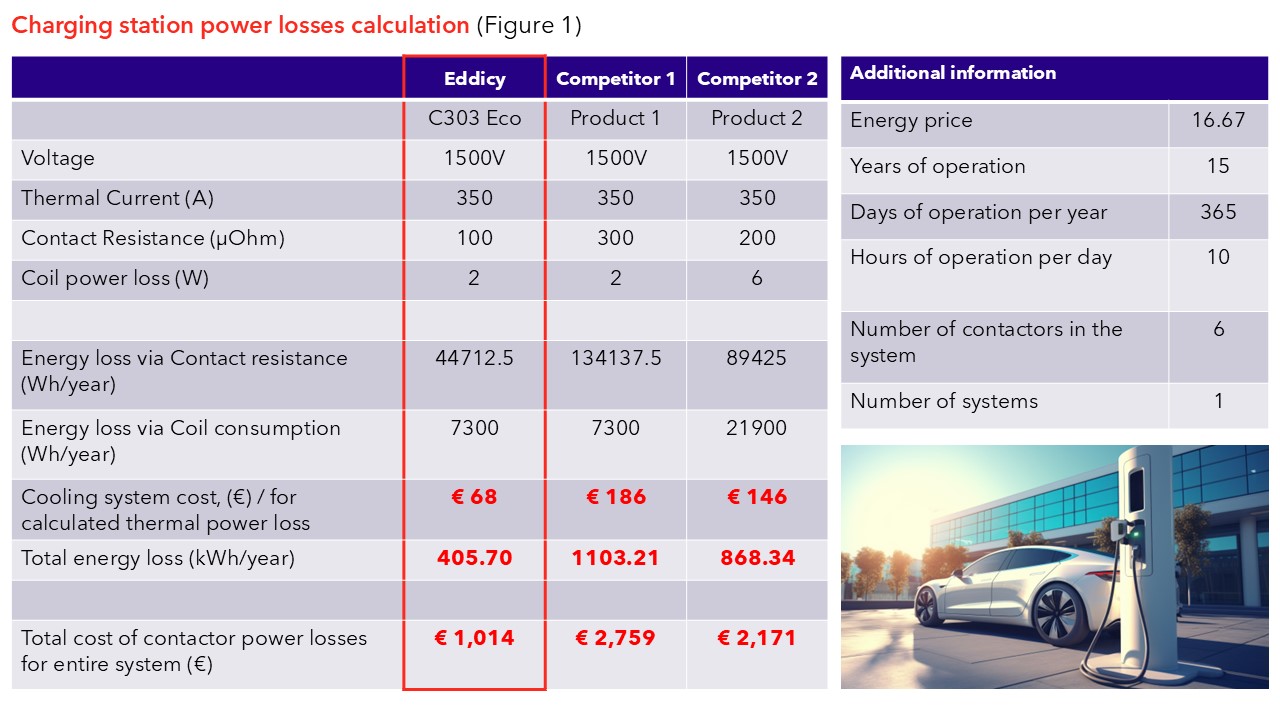

Electric charging station power loss calculation

Indeed, minimizing power losses in your contactor add up quickly (s. Figure 1): A charging station, for instance, which deploys 6 contactors (two contactors per gun and two contactors for the switching matrix), will lose about EUR 1,014 in contactor power losses for the charging station over 15 years of operation with the C303 Ecosave, but a whopping EUR 2,759 or EUR 2,171 with competitor contactors, respectively.

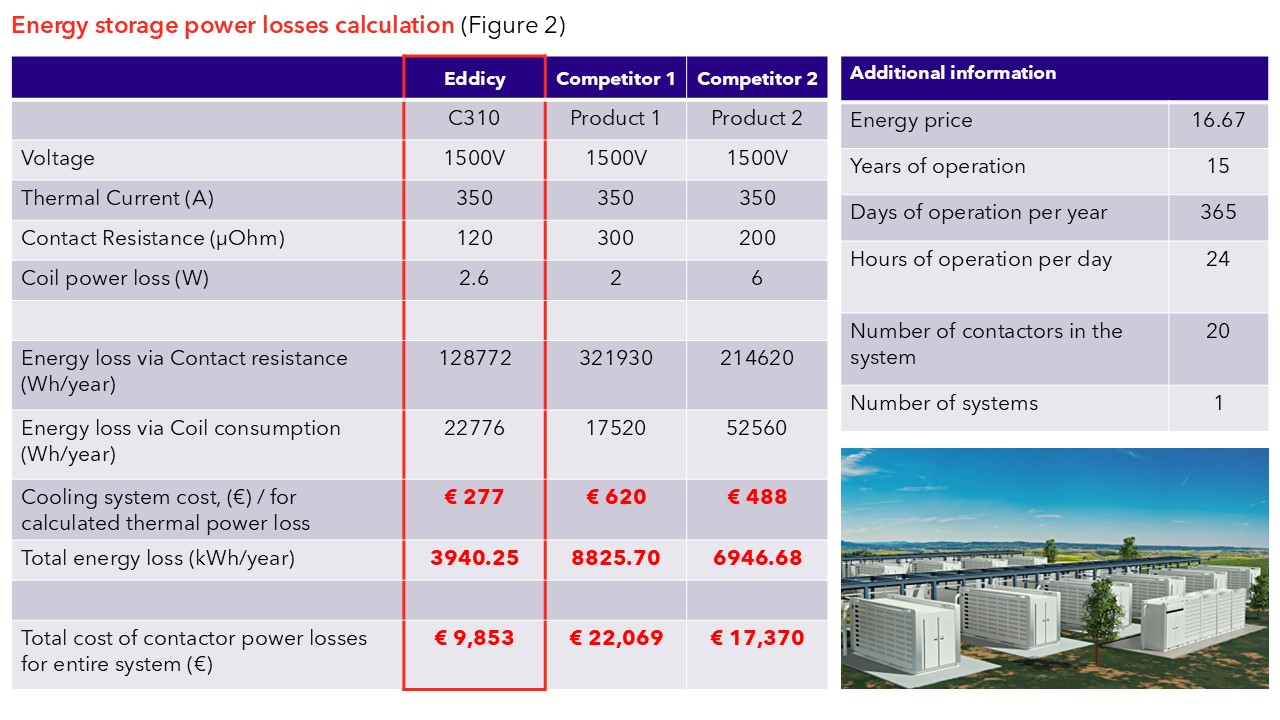

Energy storage system power loss calculation

The cost difference widens significantly in higher current applications that run 24/7, such as energy storage systems (s. Figure 2). In a large system with 20 contactors, the total contactor power loss for the entire system over 15 years of operation is EUR 9,853 with an Eddicy C310 contactor but rakes up to EUR 22,069 and EUR 17,370 with competitor contactors. Hence, making a purchase decision based purely on the price of the component might lead to unnecessarily high operational costs down the road.

Energy efficiency: “First fuel” for the energy transition

As the International Energy Agency points out, energy efficiency is the “first fuel” in the energy transition as it provides some of the quickest and most cost-effective CO2 mitigation options while lowering one’s energy bill. By accounting for energy efficiency, operational reliability, and service longevity, TCO helps to illuminate how premium components deliver twin imperatives: substantial cost savings over the product lifecycle and advancing sustainability objectives. For this reason, economic optimization and sustainability become complementary forces rather than competing priorities in the journey toward electrification and decarbonization.

Interested in your personalized contactor TCO analysis? Download our TCO calculator here to see the potential savings in your application – or

Want more information or a quote?

Please contact sales@tinex.no